Age: 18

School: West Coventry Academy

Job title: Quality Engineer

Company: Technoset

Inspired by his dad and grandad, Tyler knew an apprenticeship was a natural fit with his practical learning style but has been surprised by how much he has already gained just 18 months into his programme! We talked to him about why he chose MTC Training, what he’s enjoying most about his role with Technoset, and how he’s using his new skills to raise money for a local charity.

Why did you choose an apprenticeship?

I knew I was more of a practical learner, and I wanted to get into industry as quickly as possible through a course that directly related to what I wanted to do in the future, so an apprenticeship was a very natural choice for me. My dad is my role model and he had wanted to do an apprenticeship when he was my age – he wasn’t able to start it in the end, and so he also really encouraged me to go for it.

Were you always interested in a career in engineering?

I developed a strong interest in engineering around Year 9 and 10 at school, and my grandad was a Quality Engineer at Jaguar Land Rover, so I was inspired by him too. I didn’t know exactly what area of engineering I was most interested in though. When I first started my apprenticeship, I was actually employed by the MTC as part of a scheme with Lloyds Bank, which gave me the opportunity to explore different aspects of engineering before I chose to pursue a career path in quality and inspection career path with Technoset.

Did you have an idea of what an apprenticeship would involve before you came to AMTC?

I knew that was a combination of time in the training centre and time at work, and that I’d be getting a qualification as well as getting a lot of industrial experience. I wasn’t expecting to learn as much as I have though! I hear from my mates who are doing apprenticeships at different colleges and they don’t enjoy it so much, whereas here you get really involved in stuff.

What are the most memorable projects you’ve worked on so far?

I’m part of a project team that’s conducting audits in the inspection room to implement LEAN principles and make working areas more efficient. Because I’m good at IT and quick to pick things up, I’ve created the project plan which will be used as a best practice blueprint for roll-out across all areas of the business. I’m proud of learning to use our Quick Vision machine too – it’s really tricky and requires a lot of expertise to operate, and I’ve picked it up really quickly.

I’m also working a charity project for Myton Hospice. It’s called the Take 40 Challenge – there are four apprentices at Technoset, and we’ve each been given £40 to create something to sell on and donate the profits to the charity. We’ve put ours toward the materials to make trolley tokens, planning out the whole process between the four of us. We’ve been running the machines on our own, checking the parts on our own, we’ve worked really well as an independent team and learned so much about the process as we’ve gone along. We’re about halfway through production now – the components have been sent off to plating, which takes a couple of weeks, and once they’re complete we’ll sell them to our co-workers, and family and friends, and at our training centres. I think most people here have a connection with Myton Hospice one way or another, so it’s great to be able to use my skills to support them.

How has the apprenticeship programme been beneficial to you and your career?

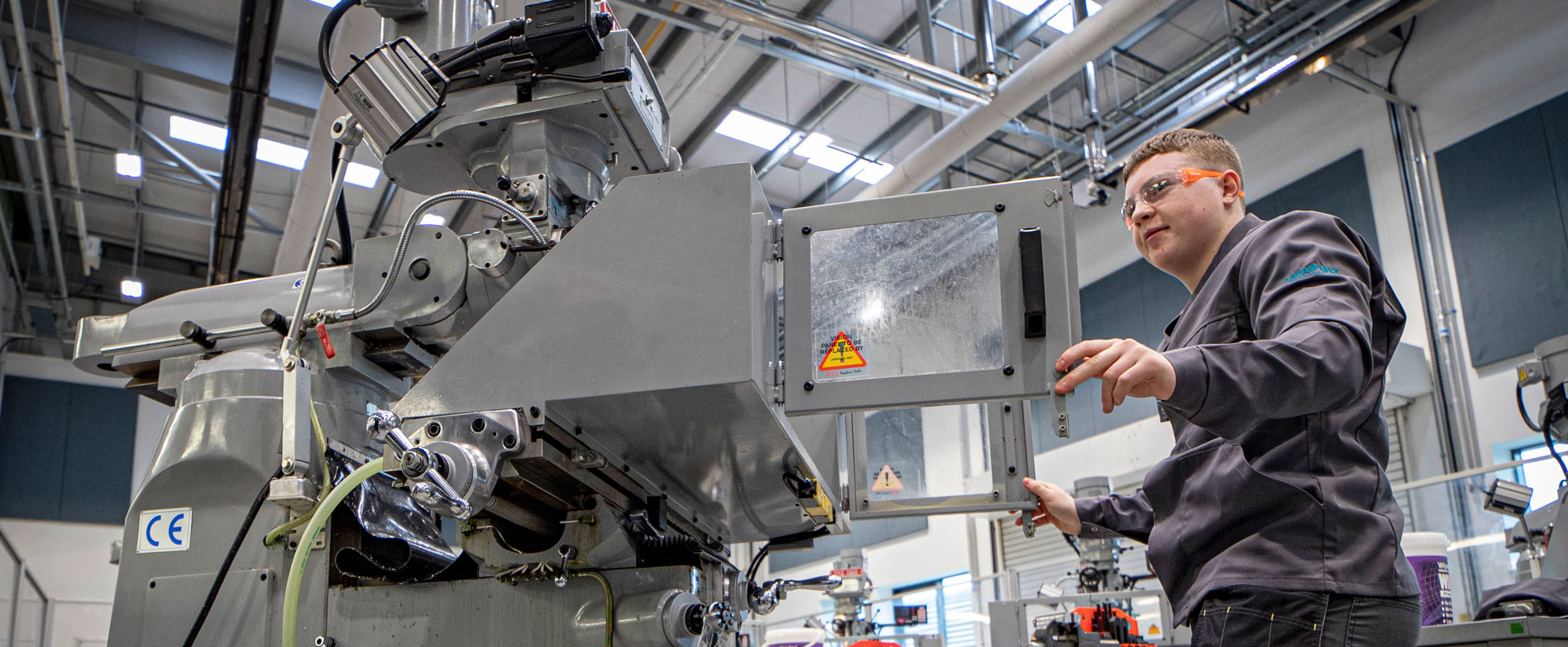

I’m only 18 months into my apprenticeship but I’ve already learned so much! I spent the first year full time in the training centre, getting a really good foundation of fundamental knowledge on processes like milling, fitting and turning. My role at Technoset is all about measuring components which are created through these processes, so the fundamentals underpin my inspecting role and give me the context, confidence and authority to work effectively.

I’m also doing extra training with the equipment manufacturers and kit suppliers, which is giving me a broader understanding of how the wider industry works. My communication skills and how I present myself have improved too because you just get involved, so you’re learning about how to communicate correctly in the situations you’re in. Experiencing it first-hand gives you confidence to do it again.

What would you say are the benefits and what advice would you offer to those looking to apply to the programme at the MTC?

When I first visited the MTC, I was blown away by the site’s facilities and the training on offer. The trainers here also take a lot of time to speak to you individually. There are weekly reviews, but also when we’re learning as a group, you can speak to a trainer one-to-one about specific things, if you’re struggling or where you’re performing particularly well. If you’re thinking about applying, I’d say go to an open day and ask lots of questions! Make sure you know what you’re applying for and that it’s what you want. It’s a good opportunity to find out what’s on offer if you don’t already have a lot of knowledge about apprenticeships.

What do you enjoy most about your work?

That I’m learning a lot, as well as all the opportunities available and the amount of time people take out of their day to show you what they do, and share their skills. I also enjoy programming the measuring machines – I like working and problem solving independently. Once a programme’s made and other people are using it, that’s a bit of a proud moment too.

What are your future career plans?

In the short term, we’re planning a week or two where I’ll be on the machines, which will give me more knowledge about the processes to be able to apply in my inspection role. Longer term, once I’ve finished my apprenticeship, I’d like to work my way up to Quality Manager.

Would you recommend apprenticeships to others?

Yes, I’d recommend them to anyone who has an interest in an industry and wants to pursue it.